News

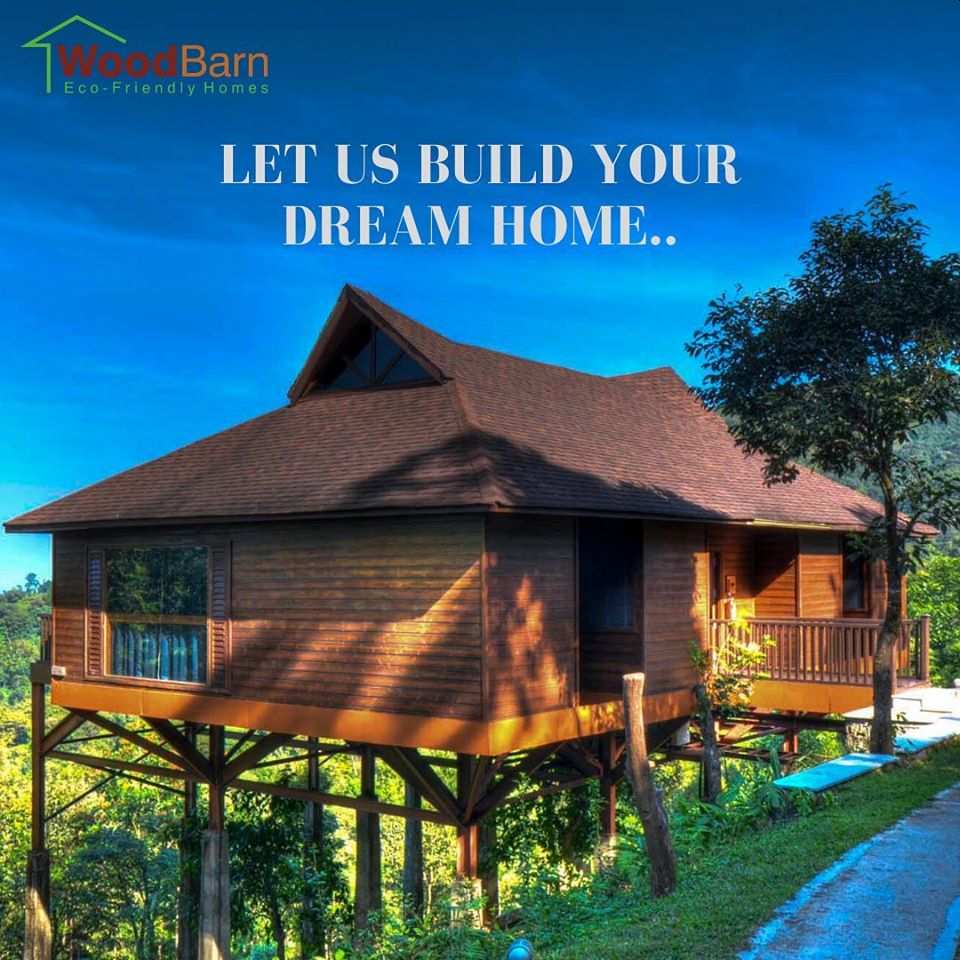

WoodBarn Constructs A House Within 12 hours

With material and applicational intelligence provided by FII, India (Canadian Wood),is able to construct a complete Resort in 1.5 Months Signs Technical collaboration with Lameco LHT Oy (Finland) for speedier Construction

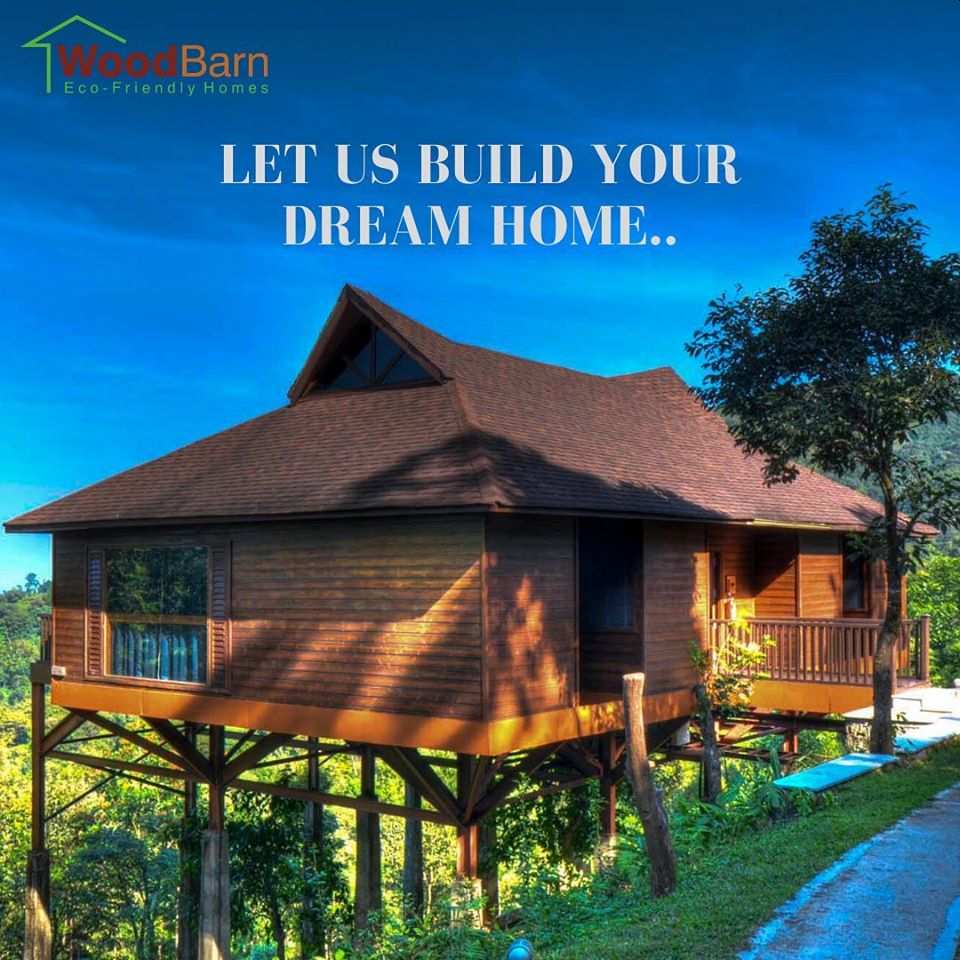

Bangalore, Karnataka, 28 February 2020: WoodBarn India, the pioneers in bringing ecofriendly Wooden houses to India is introducing the fastest construction times for any House or resort in India. The effort has been made possible with its tie ups with Lameco LHT Oy (Finland) and Canadian Wood.

These houses / cottages are being introduced at the current India Wood exhibition being held at Bangalore International exhibition Centre at the Canadian Wood booth. The Tongue and Groove (T&G) style house was made with Spruce-pine-fir, a sustainably sourced Canadian wood species that is ideal for structural applications due to its strength and dimensional stability. More species of Canadian wood were used to embellish the interiors of the house. For example, Western hemlock an evolving preferred choice of furniture manufacturers in India due to its looks and workability was used for furniture. While the doors and door frames were made with Yellow cedar which is a high-quality substitute wood in lieu of UPVC windows that cancel out noise, dust and water.

Mr. Sanjay Sharma, Chairman & Managing Director, Wood Barn India Pvt Ltd., said “WoodBarn, in India has already been working with Canadian Wood for providing eco-friendly wooden structures. Our new agreement with Mr. Ismo Rautiainen’s Lameco LHT Oy helps us in expediting up the entire process from 36 hours earlier to 12 hours now. This will help us in further conserving potable water as well as provide more energy efficiency”.

Mr Pranesh Chhibber, Country Director, FII India (Canadian Wood) said, “The hospitality industry is increasingly looking at building resorts using wood in structural applications. Also, there is an upward trend in increased usage of wood in the home category by leading architects, manufacturers, HNIs looking at villas, country homes and farmhouses as a lifestyle statement. Canadian wood on its part is doing its bit in promoting building with wood through technical support and handholding in the T&G, WFC & Post & Beam method in addition to the hybrid method of building with wood and local stone/brick besides interior and exterior use of wood in more traditional applications such as panelling, cladding, furniture (indoor & outdoor), joinery – doors & windows and pergolas/gazebos etc.”

Besides the short time needed for construction of such structures, it is also an environment friendly structure with minimum carbon footprint. As research shows that wood products need the least amount of energy to manufacture, and that this process has the lowest impact on air and water quality. Using wood can offset climate change since trees absorb carbon dioxide as they grow, and the resulting products continue to store much of this carbon for decades or even centuries. For example in North America, a typical wood frame home stores 29 tonnes of carbon –this represents the amount of carbon dioxide emitted by running the family car for five years.

Mr. Ismo Rautiainen said, “Lameco LHT Oy has considerable experience in the line of manufacturing these Wooden houses and resorts. Our arrangement will be such that Lameco LHT Oy will provide technical know-how to WoodBarn India with technical know-how and advice for the purpose of improving or starting the factory and installing the plant and machineries for the manufacture of wooden structures.

These wooden structures are unique in themselves displayed a blend of modernity, absolute functionality and aesthetics, that are in tune with nature and in India are already being used by leading resorts like Tamara Coorg. Pancheri, ITC Dharamshala, Some of the club Mahendra Properties, Radisson Blu Dharamshala among others

Woodbarn India promises, not just a environment friendly house, but also fire, earthquake and termite resistant. Moreover, it is water proofed with heat and Sound insulated and is highly cost efficient. The wood is versatile, adaptable, easy to dismantle and can reassembled.

The Canadian Wood in Kiln dried and heat treated and the moisture content is limited to 15-18% to make the wood Resistant to weathering and termites. The base floor woods are ACQ treated to make the structure more resistant to termites and insects.

Research and experience has revealed that wood-frame construction offers the following benefits:

Increased thermal performance: Wood-frame construction is easy to insulate to RSI 2.62 or higher, meaning increased resident comfort and much lower heating and cooling costs over the life of a building.

Architectural flexibility: It is economically feasible to add offset walls, balconies, alcoves and other features that add interest and appeal, especially for roofs.

Space economy: Wood-framing is compact – structure, insulation, air and moisture barriers and exterior and interior finishes are contained in a small, light-weight space.

Durability: Falsifying the myths of the less durability of wooden framed houses. There are many examples of wood buildings that have lasted hundreds of years, and modern wood-frame construction is better equipped than ever to last at least as long as a building is still meeting the user’s needs.

Ease of installing electrical and mechanical services: Interior wall and floor cavities are used to route vertical and horizontal services, including electrical wiring, plumbing, and heating ducts.

Affordability: The major reason why wood-frame construction has been so successful in North America, and the rest of Europe who are adopters is that it is being considered by many countries to solve housing challenges, is its affordability.

Construction speed: Wood-frame construction is fast – it is normal for an experienced crew of three to frame one floor per day per unit. In countries where wood-frame construction is new, an adaptation period is required before the speed of wood construction can be realized. In recent adopters such as India, wood-frame construction can still offer initial savings in time and costs, and greater savings as familiarity builds.

Meeting building codes: Based on research and testing, wood-frame construction meets or exceeds building code requirements for strength, sound transmission and fire safety.

And lastly wood as a construction material is versatile, adaptable, easy to dismantle and can be reassembled, the result is that wastage is minimized in reclamation is an easy process.

-

News3 weeks ago

News3 weeks agoKW Delhi 6 Mall Onboards New Brands

-

News4 weeks ago

News4 weeks agoManasum Senior Living Launches IKIGAI GOA, A Senior Living Community in North Goa, in collaboration with Prescon Homes

-

News2 weeks ago

News2 weeks agoGodrej Properties Sells Rs 3k cr+ Homes of Godrej Zenith, Gurugram, within 3 days

-

News4 weeks ago

News4 weeks agoBridging India Divide: Top 5 Tier- 2 Cities to Focus On

-

News3 weeks ago

News3 weeks agoCommercial Realty Gets Tech Savvy: Fast Construction, Enhanced Convenience

-

News4 weeks ago

News4 weeks agoMultipoint Connection – A Definite Boon

-

News3 weeks ago

News3 weeks agoRBI’s Status Quo on Key Policy Rates to Help Maintain the Real Estate Growth Momentum, Say Industry Stalwarts

-

News1 week ago

News1 week agoOlive Announces Dhruv Kalro as Co-Founder